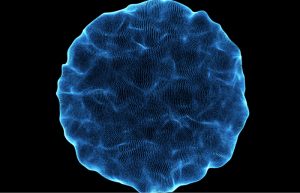

Dassault Systemes is shaking things up in India’s aerospace and defense sector. How? With Virtual Twin technology! Powered by the 3DEXPERIENCE platform, this tech lets companies design, test, and perfect their creations in a virtual world before they hit the production floor. That means fewer mistakes, better efficiency, and smarter innovations.

What is Virtual Twin Technology?

Consider it a super-detailed digital clone of real-world assets like aircraft and satellites. These virtual twins allow companies to test aerodynamics, structural strength, and overall performance—all before creating physical prototypes. This not only saves time and money but also ensures top-notch quality and safety.

Boosting Manufacturing & Performance

Virtual Twin technology isn’t just about designing cool aircraft. It also streamlines production. By simulating manufacturing processes, companies can identify weak spots, minimize waste, and optimize efficiency. Plus, real-time data integration makes predictive maintenance a breeze, ensuring defense assets last longer and perform better.

A Big Win for Sustainability

Sustainability is the future, and Dassault Systemes is leading the way. With Virtual Twin technology, companies can test fuel efficiency, emissions, and material use. This means greener aircraft, lower waste, and a major step toward eco-friendly aviation.

Dassault Systemes is also teaming up with the Indian government to push sustainable aerospace initiatives. From funding green technologies to supporting SMEs, they’re helping the industry move towards a cleaner, smarter future.

Tackling Challenges Head-On

Sure, sustainability tech sounds amazing, but it’s not all smooth sailing. High costs, complex regulations, and supply chain hurdles make adoption tricky. But Dassault Systemes has a solution—real-time testing and AI-powered simulations. These cut costs, improve designs and make sustainability more accessible for companies.

Investing in Skills & Innovation

Dassault Systemes isn’t just transforming technology; they’re also shaping the future workforce. They invest in training programs, collaborate with universities, and have set up Centers of Excellence across India. Engineers are trained in advanced platforms like CATIA, DELMIA, and ENOVIA, ensuring they’re industry-ready.

The Bottom Line

Virtual Twin technology is a game-changer for India’s aerospace and defense sector. From reducing costs to making aviation more sustainable, Dassault Systemes is setting the stage for a smarter, greener, and more efficient future. And this is just the beginning!